Please Wait |

Please Wait |

Esscoat implements the minimal coating thickness thanks to its outstanding refractory performance

More precise ultrafine hollow bodies and the optimal combination design of Esscoat product not only enable the thinnest refractory coating thickness in a Korean product, but also deliver the world's highest level of refractory.

Asbestos and Vermiculite-free

Esscoat is an asbestos-free product made of perlite, which is free from hazardousness of asbestos-containing materials.

Eco-friendly construction materials

Esscoat has obtained environmental mark certification (environmental mark) and eco-friendly construction material certification (HB0 mark) with the highest rating.

Outstanding constructability and quality stability

Thanks to its ‘ball bearing’ effect created by globular superfine hollow bodies, it not only offers outstanding constructability and dimensional stability, but also does not require surface coating for dust prevention, and is not

prone to peeling-off, cracks, rust, etc.

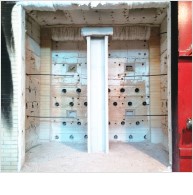

How to Use Esscoat

1-Preparation

2- Application

3-Curing

Curing should be carried out in a place with appropriate ventilation, and rapid drying during curing should be avoided. The curing periods are listed in the table below.

What is UL?

UL stands for Underwriters Laboratories, which was founded in 1894 and is one of the representative non-profit certification authorities in the US in the field of industrial safety. UL establishes various safety standards and grants certifications, and is one of the most authoritative safety certification authorities.

Esscoat UL is a product that was developed with the goal of obtaining UL certification, and has secured a level of product competitiveness that differentiates it from other existing products.

What is UL263?

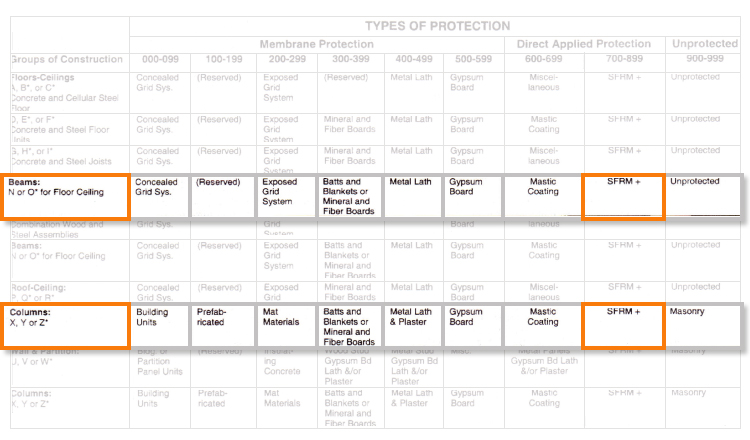

UL263 is the “Fire Test of Building Construction and Materials.” Of the various refractory materials, coating materials such as Esscoat are classified into the SFRM (Spray-Applied Fire Resistive Materials) category.

Details of UL certification:

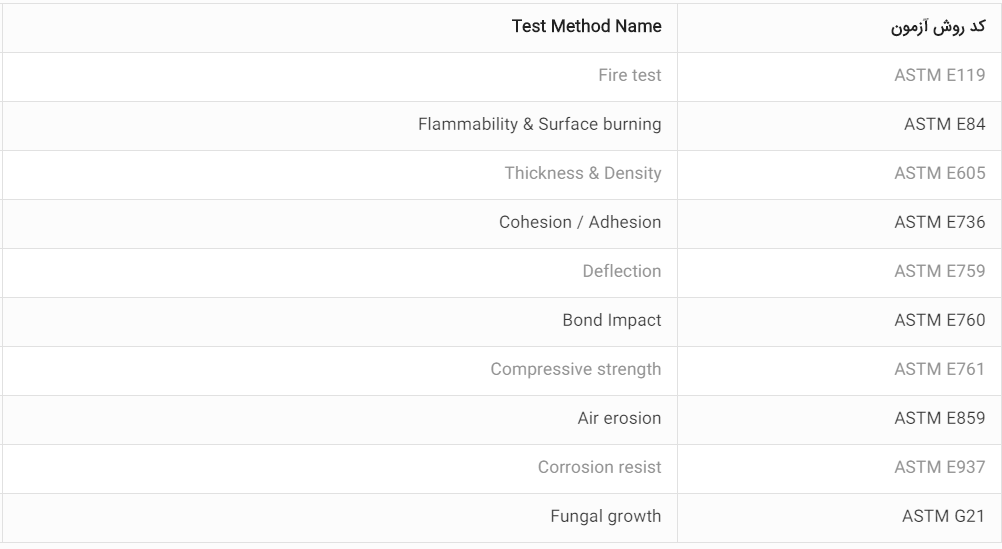

1- ASTM

ASTM International, originally the American Materials and Testing Association, is one of the largest international standard development organizations.

The extensive standards of this organization, which include technical standards for materials, products, systems, and services, are approved by consensus (members' agreement). The organization has 30, 000 members from 120 countries.

Unlike other standard institutions, such as BSI, DIN and AFNOR, ASTM is not a governmental organization. In accordance with the existing instructions for fire resistive spray- applied materials such as ESSCOAT is required for the following tests. ESSCOAT material test results are above standard limits.

2- Healthy Building Material (HB)

HB's goal is to facilitate the sustainable development of clean air, quality management, and domestic environmental control, as well as to enhance environmental protection through improved air quality.

The ESSCOAT material has the highest mark on this organization with five green leaves, a substance with a complete environmental compatibility.

3- CE

The CE trade mark is presented to create co-ordination in many commercial and industrial products that are produced or marketed in Europe. In general, they can be cited by the words "Communauté Européenne" or "Conformité Européenne", meaning "acceptable to Europe".

Products that qualify for the CE mark. They should be considered in terms of health, safety, harmfulness to the human body and nature, and if they are eligible, they will be able to get that sign.